Custom-made Resibon prepreg composites

Four strength to support your business.

-

POINT:01

Wide size impregnation

Impregnation width up to 1,600mm.

-

POINT:02Extensive vendors

Variety of materials available from domestic/international vendors

-

POINT:03Short run production

Lot production available from 50m length

-

POINT:04Short lead time

Shortest delivery by 2 weeks from receipt of PO.

Prepreg composites

Prepreg composites are intermediate goods which variety of fibers, such as glass cloth and carbon fiber,are impregnated into thermal resins and dried into partially cured state.

-

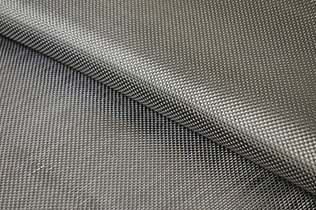

【Fabric】

Fiberglass, carbon fiber, etc. -

【Resin】

Phenol, epoxy resin, etc. -

【Composite Material】

Prepreg

Applications

Reinforcement for abrasive grinding wheels, Reinforcement for tunnels and bridge piers, Helmets, Wire mesh for mosquito coils, Automobiles, Aircrafts, Wind power generators, and Materials for CFRP.

Variety of compositions are available for each applications

Preperg composites have various composition of fibers and resin. Our domestic and international supply network enable custum-made production suites to clients application.

Custom-made preperg composites available from material selection

Variety of custom-made prepreg composites available upon request.

Adjusting mixture of resins depending on demand. Specific resin mixtures available upon request.

Consulting the selection of base materials depending on client's demand.

Delivery available in roll, sheet cut to length, and die cut.

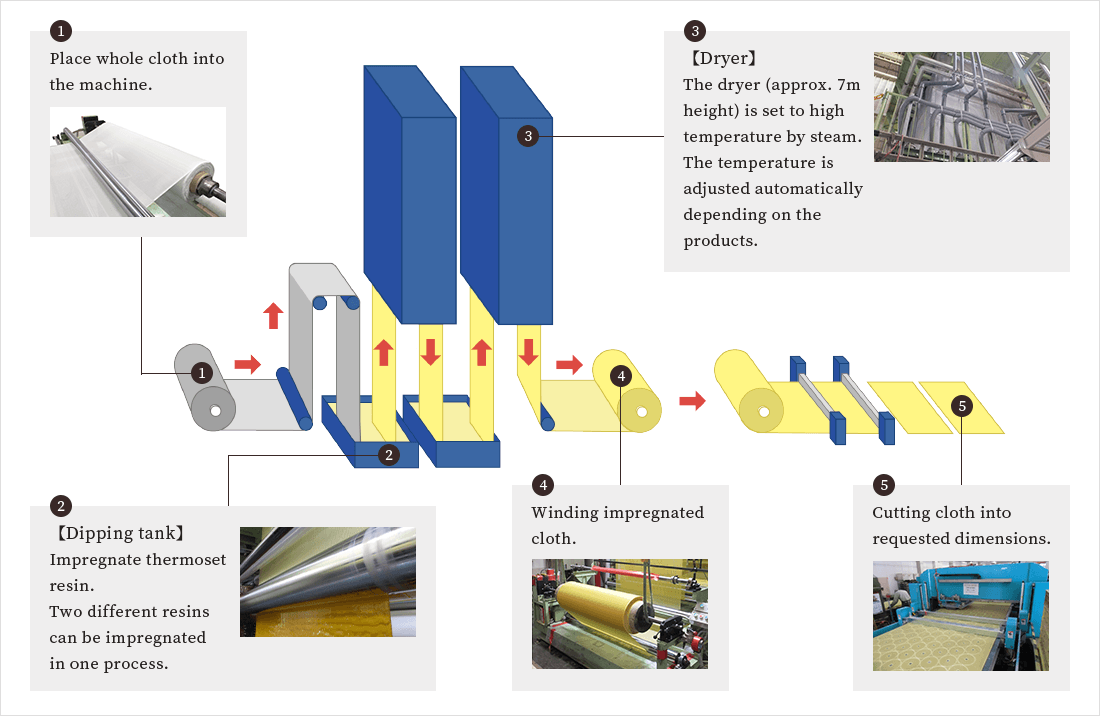

Production process of prepreg composites

List of materials

【Resin】

- Epoxy

- Phenol

- Melamine

- Unsaturated polyester

【Fabric】

- Glass

- Carbon

- Aramid

- Basalt

- Polyethylene

- Aluminum evaporation glass

- woven cloth of left fabric and non-woven cloth

Production Overview

Full support from product development to lot production.

-

STEP:01

Selection of materialSelecting suitable material for client's demand. Supplied material from client is also available.

-

STEP:02

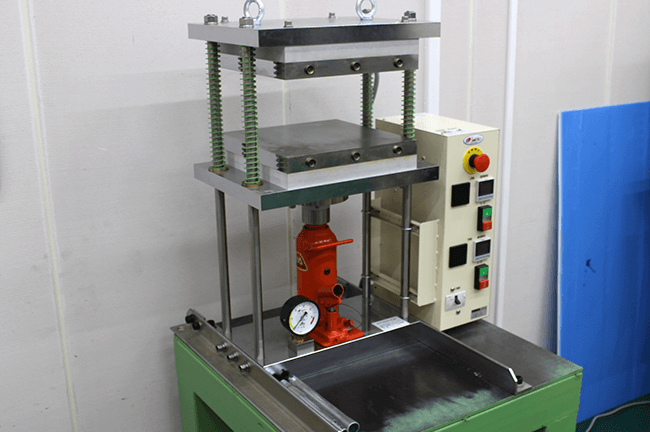

Small trialsSmall size trials available for testing.

※Sizes available from A4 to A3.

※Trial molding available in 200mm square. -

STEP:03

Trial samples in 3 production machineProducing trial sample with our production machine available per one hour

※The machine will be operated by our staff. -

STEP:04

ProductionLot production available from 50m length.

Facilities

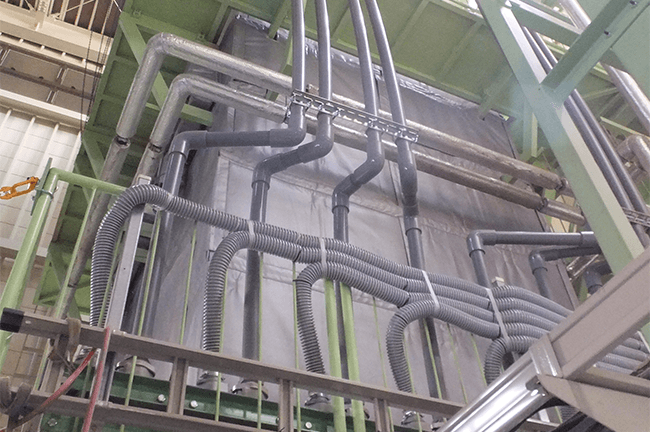

Impregnation machine

Automatic cutting machine

Experiment room

Prototype machine

Tensile tester

Manual hot press

Department Overview

| Location | 358, Kamiokacho Azumo, Hida, Gifu 506-1147 |

|---|---|

| Business | Manufacturing and distribution of pregperg composites |